Welcome to the ultimate guide on Inconel 625 welding rod! Inconel 625 is a widely-used Nickel-based alloy commonly found in high-pressure and high-temperature applications. With excellent mechanical properties, corrosion resistance, and high-temperature strength, Inconel 625 welding rod is a popular choice in various industries, including petrochemical, aerospace, and marine. In this blog post, we will closely examine the properties, characteristics, and applications of the Inconel 625 welding rod.

What is Inconel 625 Welding Rod?

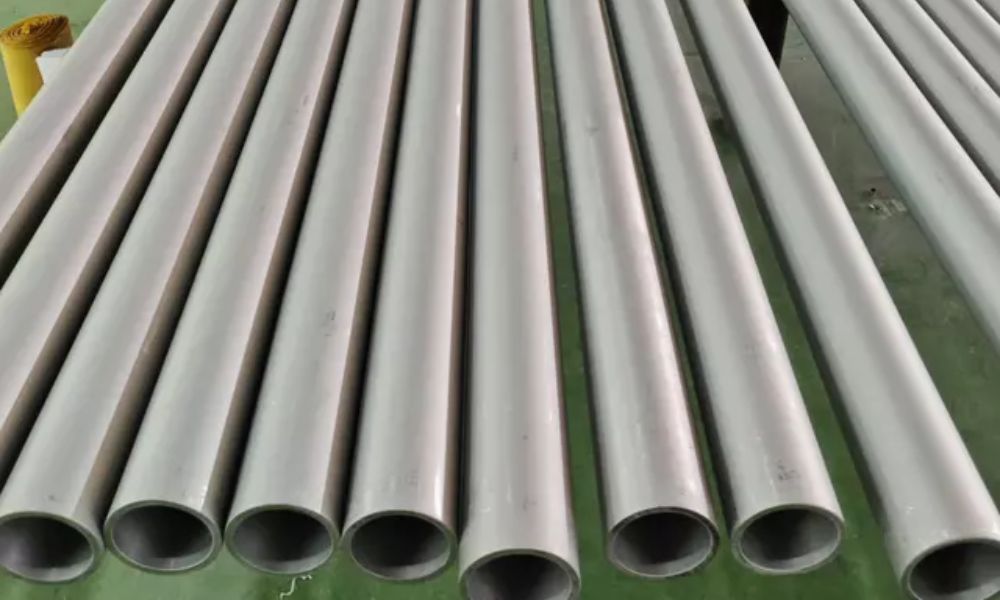

Inconel 625 Welding Rod is a nickel-chromium-molybdenum alloy used for welding materials that require superior resistance to corrosion and high temperature. Even in extreme temperatures, it has excellent strength and toughness, making it useful for many industrial applications such as steel production and petrochemical processes. Its low thermal expansion coefficient makes it ideal for welding pipes subject to stress or vibration.

Properties

Inconel 625 welding rod is a Nickel-based alloy that contains Molybdenum, Niobium, and Chromium. It has a tensile strength of up to 1350MPa and can withstand temperatures up to 980°C. Inconel 625 welding rod also has excellent corrosion resistance, especially in seawater, making it an ideal material for marine applications. Furthermore, it has high fatigue strength, good weldability, and low magnetic permeability.

Characteristics

Inconel 625 welding rod is known for its outstanding resistance to pitting, crevice corrosion, and stress corrosion cracking. It’s also resistant to various acids, including sulfuric acid, hydrochloric acid, and nitric acid. Additionally, it’s highly resistant to oxidation and scaling at high temperatures, making it an ideal material for high-temperature environments. Inconel 625 welding rod also has good ductility, making it easy to form and machine.

Applications

Inconel 625 welding rod is used in various industries, including aerospace, chemical, marine, and petrochemical. It’s commonly used in gas turbine parts, engine exhaust systems, and fuel nozzles in the aerospace industry. It’s used in heat exchangers, valves, and reaction vessels in the chemical industry. In marine applications, it’s used in seawater corrosion-resistant equipment, such as propeller blades, splash zone sheathing, and seawater piping systems. In the petrochemical industry, it’s used in wellhead components, downhole equipment, and oil and gas production equipment.

Conclusion:

In conclusion, Inconel 625 welding rod is a highly versatile material with excellent mechanical properties, corrosion resistance, and high-temperature strength. Its good weldability, low magnetic permeability, and high fatigue strength make it ideal for various applications. From aerospace to petrochemical, Inconel 625 welding rod has proven reliable and durable in the most demanding environments. If you’re looking for a high-performance alloy that can withstand the toughest conditions, Inconel 625 welding rod is an exceptional choice.